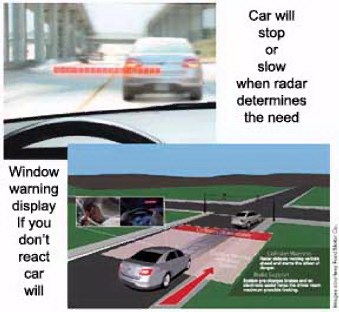

Drive by Wire

The Dream Becomes an Incremental Reality

The drive-by-wire concept calls for the transfer of the control of a vehicle from the driver to an automated system that controls the vehicle’s steering, engine throttle, and brakes.

Today’s automotive engineers are now taking an incremental approach to turn new car safety technologies, over time, into an autonomous vehicle navigation drive-by-wire system.

How close are we now to the dream?

Self-Healing Materials A New Material-Science Breakthrough

Today's construction materials corrode or just disintegrate over time. Infrastructure built with these materials eventually need repair or replacement.

New self-healing materials can repair their own structures without human intervention.

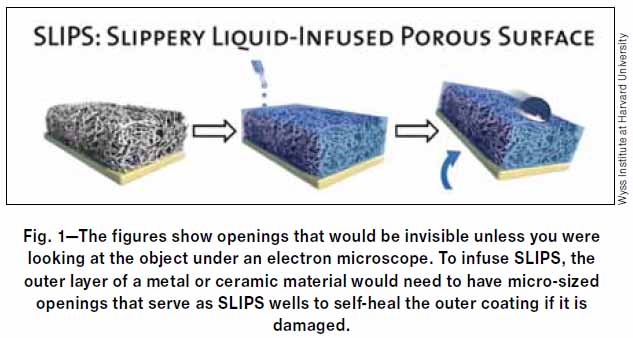

Electron Microscope Image

The Robotic Parking Garage

This garage replaces ramps, driveways and parking attendants with a robotic system that squeezes 67 cars into an area that conventional parking could at best only fit 24. Your car is transported to its parking space by a multitasking robotic system that includes a great deal of redundant computer power to prevent accidents.

The cars are stored two deep. If the car against the wall is the first one to be picked up, the robotic system jockeys the front car to another location to gain access to the buried car. The system even includes a rotating table that turns the vehicles around before they are lifted back up to the drop-off/pick-up point in the lobby of the garage.

"Cellular Aluminum"

Up until now, it was impossible to increase the energy absorption zones of a car without dramatically increasing the car’s weight. Metcomb Nanostructures, has made a metallurgic and manufacturing breakthrough that should soon revolutionize the way car crush zones are made.

When the company’s cellular aluminum is layered with other materials it not only absorbs the energy of car crashes, it can also absorb the energy of bullets and bombs while holding onto their fragments.

"The SHIFT Bike"

Once the bike is in motion the section where the two rear wheels touch the ground move closer together transferring the balancing act from the bike to the rider. As the bike slows down the opening of these two rear wheels once again expands making it much easier for the new rider to learn how to safely stop the bike.

From Printed books to Digital

Searchable Files

Searchable Files

A book to be scanned is first placed in the bed of the machine. When the machine is activated a set of vacuum fingers gently lifts and a machine arm turns the page. The arm carries the page over to the opposite side of the book to expose the next two pages for scanning.

"THUMS"

Engineers at Toyota Motors asked themselves this same question back in 1996. For the last eight years they have been quietly developing the technology that will eventually place most automobile industry test dummies on unemployment lines.

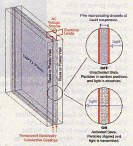

"Smart Windows"

The change in transparency of SPD glazing materials is a reaction to an electrical voltage change that affects suspended particles that are sandwiched in a middle layer of film in the glass.

"The Personal Airbag"

A vest that brings the safety net of an airbag to individuals exposed to dangers without the safety cage of a car or other vehicle.

Parachute Away (Full Plane Parachute)

In just one second this simple action would cause a solid fuel rocket to pull the parachute out from the mounting on the airplane's fuselage and carry the parachute at over 100 miles per hour to its opening position above the airplane.

Cambridge Crude

The MIT Liquid Fuel in a New Battery Architecture

The MIT Liquid Fuel in a New Battery Architecture

The future automobile will run on electricity not gasoline! This could quickly happen if you could pull up with your EV to a "gas" pump to recharge your car with a liquid electric fuel.

Cambridge Crude, the nickname of a new Massachusetts Institute of Technology (MIT) liquid battery recharging system will let you do just that. This new liquid charge goes in as the old one goes out for re-charging by the fueling station; to be used over and over again.

Cambridge Crude, the nickname of a new Massachusetts Institute of Technology (MIT) liquid battery recharging system will let you do just that. This new liquid charge goes in as the old one goes out for re-charging by the fueling station; to be used over and over again.

MIT "Engine"

Turns a Liquid into Electricity

Turns a Liquid into Electricity

The Friction-Stir Welding process welds metals without melting them. It works on metals including aluminum, a metal that cannot easily be joined using other metal fusion processes.

NASA engineers have recently reengineered this technology so that it can now be used on materials that vary in thickness and even weld objects with very complex shapes.

NASA engineers have recently reengineered this technology so that it can now be used on materials that vary in thickness and even weld objects with very complex shapes.

Friction-Stir Welding

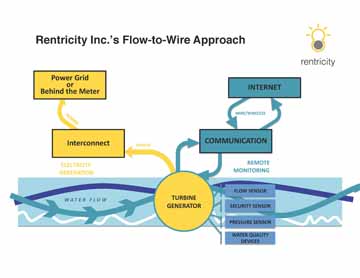

The flowing water in your home can be turned into electricity. With funding from the New York State Energy Research and Development Authority, Rentricity is starting to prove that you can turn flowing drinking water into electricity. Their engineers are now installing new valve/generators that will use wasted pressure to generate electricity.

Generating Electricity From Drinking Water

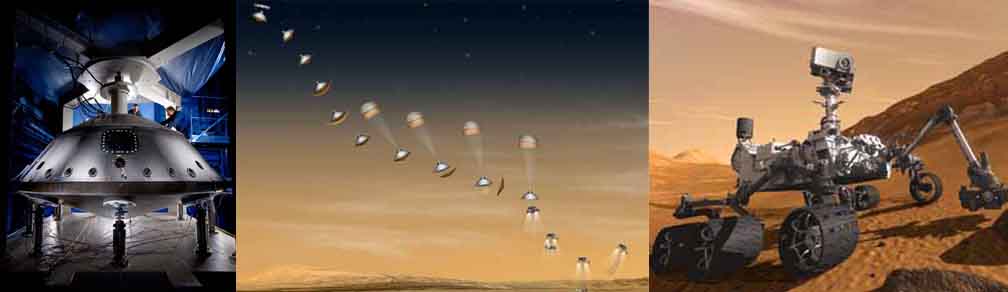

From liftoff to landing,Curiosity flew 352 million miles in 245 days. Because of the

distance between planets, NASA Mission Control didn’t even know if the landing worked until Curiosity had been on the ground for seven minutes.

The computer controlled landing depended on a computer program that contained half a million lines of code. Why and how this landing succeeded is covered in this column.

distance between planets, NASA Mission Control didn’t even know if the landing worked until Curiosity had been on the ground for seven minutes.

The computer controlled landing depended on a computer program that contained half a million lines of code. Why and how this landing succeeded is covered in this column.

The Curiosity Martian Landing

Baxter the Unconventional Robot

Baxter the unconventional robot writes its own programming code. Baxter is a new type of robot, with toy-like features, that has been designed to work next to people.

Baxter was created by Rodney Brooks the former director of the MIT Artificial Intelligence Laboratory. Before he established Rethink Robotics and created Baxter, he founded iRobot. A company that builds consumer robotic cleaning machines, military warrior bots, and rescue robots. Rodney Brooks is called the go-to guy for artificial intelligence, computer vision, and robotics.

Baxter was created by Rodney Brooks the former director of the MIT Artificial Intelligence Laboratory. Before he established Rethink Robotics and created Baxter, he founded iRobot. A company that builds consumer robotic cleaning machines, military warrior bots, and rescue robots. Rodney Brooks is called the go-to guy for artificial intelligence, computer vision, and robotics.

You learned in science that vulcanization is a process that changes the structure of rubber, making it indestructible. The Fraunhofer Institute of Germany and two American companies have demonstrated that they can turn old vulcanized rubber tires into a powder that can once again be bonded together by the heat and pressure of an extrusion machine or the injection molding process. The full story tells how they are now starting to turn old rubber particles into new high quality products.

Reversing the Vulcanization Process

Reversing the Rubber Vulcanization Process

The Paperless Office

The vision of a “paperless office” dates back to 1975 and the “paperless society” has been around since 1978.The same technology breakthroughs that ushered in the predictions that paper would become irrelevant to communication are now about to guarantee that paper will continue to play a significant role in electronic communication.

In the future our society will depend on new paper products. The next generation of Electronic Circuits will be built on a paper substrate.

The vision of a “paperless office” dates back to 1975 and the “paperless society” has been around since 1978.The same technology breakthroughs that ushered in the predictions that paper would become irrelevant to communication are now about to guarantee that paper will continue to play a significant role in electronic communication.

In the future our society will depend on new paper products. The next generation of Electronic Circuits will be built on a paper substrate.

The Paperless Office

+ Time c

=s A Paperless Society?

or a shift to new Electronic circuits built on paper.

+ Time c

=s A Paperless Society?

or a shift to new Electronic circuits built on paper.

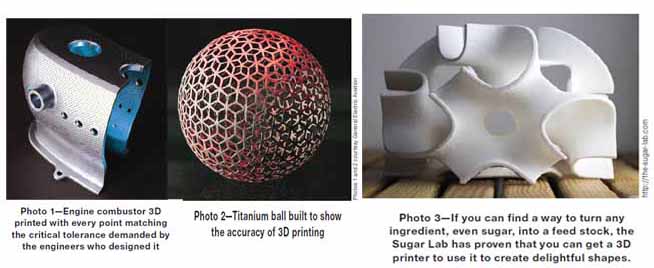

Today General Electric’s aviation division and NASA are both creating engine parts on a 3D-printer. Their industrial 3D-printing process is called Additive Manufacturing. It is a 3D printing machine on steroids. The parts that they are producing can handle 6,000 degrees Fahrenheit. Watch this NASA video.

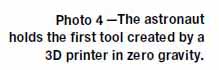

On the do it yourself side of 3D printing you can make just about anything even if you don't own a 3D printer. Read the full story to learn how. This technology is now being used to create tools, weapons, machine parts, and food. In high tech medical laboratories it is actually being used to create human tissues and organs for transplantation.

On the do it yourself side of 3D printing you can make just about anything even if you don't own a 3D printer. Read the full story to learn how. This technology is now being used to create tools, weapons, machine parts, and food. In high tech medical laboratories it is actually being used to create human tissues and organs for transplantation.

3D Printing

From the Simple to the Complex

From the Simple to the Complex

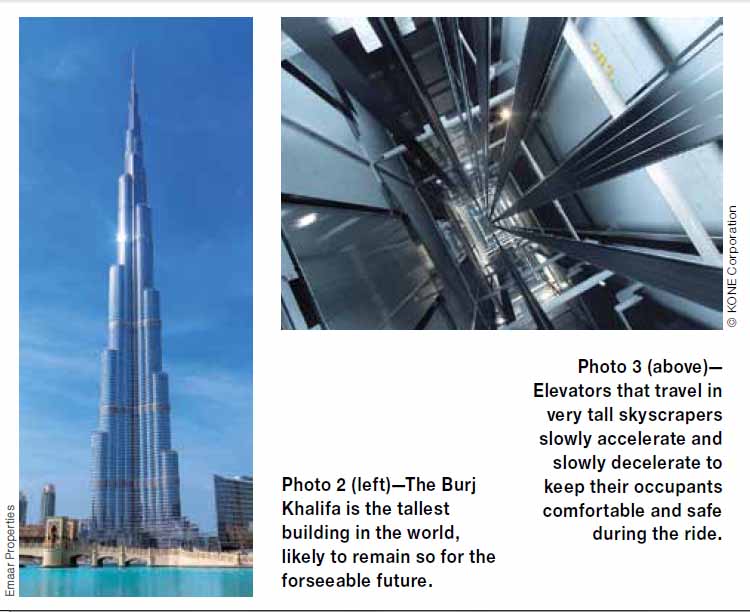

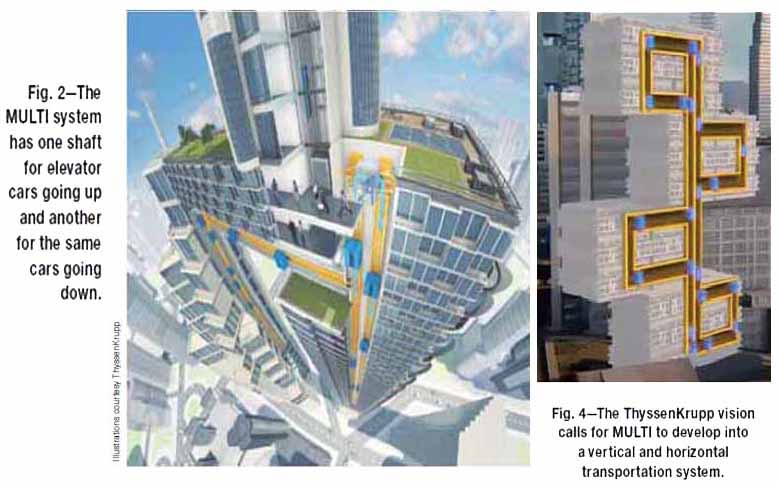

The modern elevator story began in 1852 with Elisha Otis’s invention of a safety mechanism that stopped elevators from falling. To take passengers on a half mile- high elevator ride in the Burj Khalifa skyscraper, the Otis Elevator Company had to build a lift system with a 100-ton capacity.

Without a major breakthrough, elevators have reached their height limits because longer cables will break under their own weight. At this time, the construction industry is evaluating KONE Ultra-Rope™ which is a carbon fiber replacement for the steel elevator skyscraper cables.

Without a major breakthrough, elevators have reached their height limits because longer cables will break under their own weight. At this time, the construction industry is evaluating KONE Ultra-Rope™ which is a carbon fiber replacement for the steel elevator skyscraper cables.

A Vertical Transportation Breakthrough

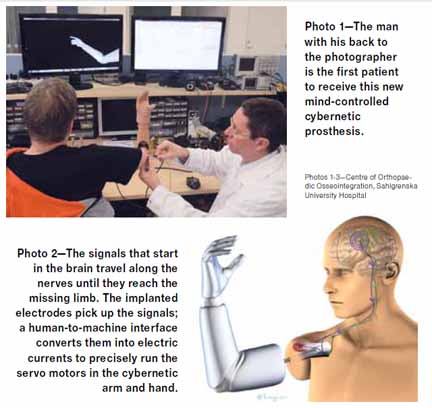

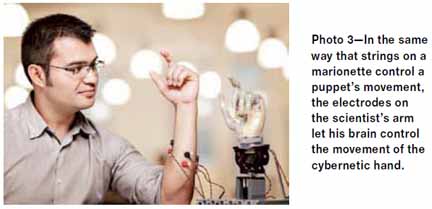

Controlling Cybernetic Machines with the Human Mind

The first cybernetic people will only have a few mind controlled parts. These parts will replace amputated arms, hands, or legs. People with these kinds of replacements are now common in Sci-Fi movies. This column explores how close we are to almost human androids and mind controlled cybernetic replacement parts for people.

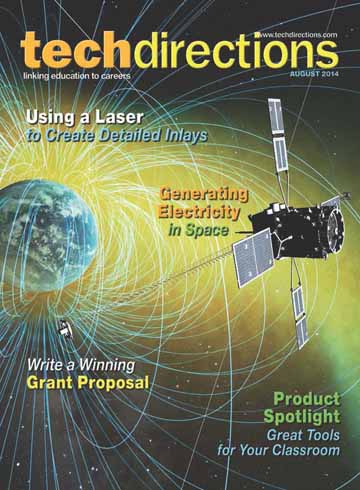

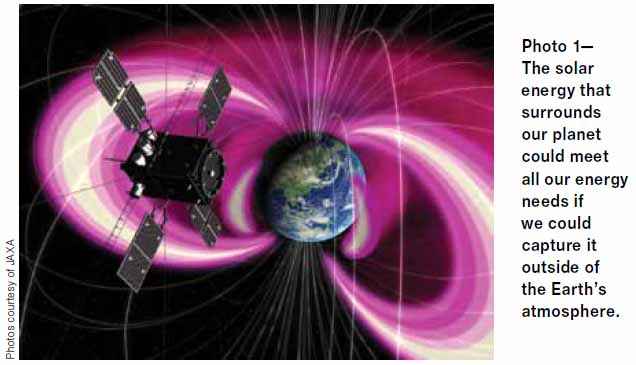

Japan to Build an Orbiting Electricity-Generating Station

If we could effectively harness the energy from the sun, we could meet all of our energy needs without ever burning another drop of oil or coal. The technology that Japan is developing could change our world. The full story is as mind boggling as these photos. Click 4 Full Story

By Alan J. Pierce EdD

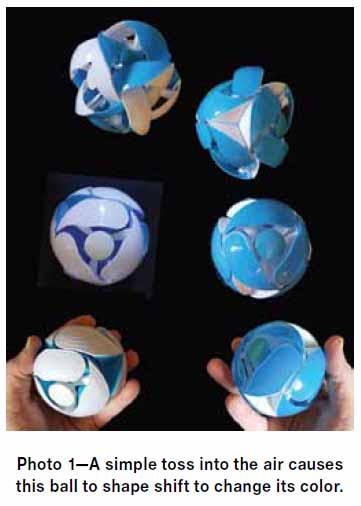

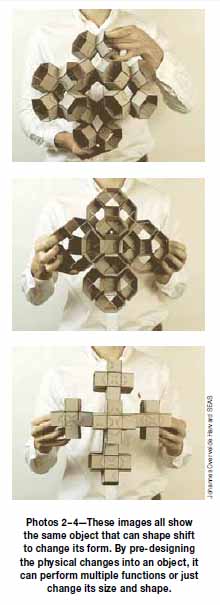

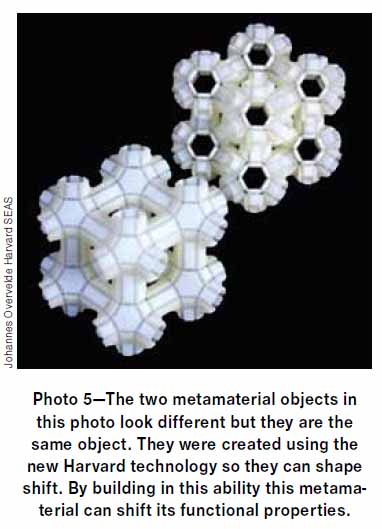

3 DimensionalTransformers

Professor Katia Bertoldi and her team of researchers at Harvard University’s School of Engineering and Applied Science (SEAS) have recently developed a mathematical transformational technology that completely automates finding the best way to form a flat material into a form that can be shape shifted to perform a number of different functions.

Using this technology a designer or engineer would provide all the size and shape parameters that needs to be achieved when the object transforms from one shape into another. The program quickly finds all the possible solutions and then selects the solution that conforms to the parameters of size and shape that the researchers want as an output.

Hypothetically using this technology you could create a habitat for astronauts that folds down flat to be transported on a flight to Mars. It can also be used to create a medical device that is so small it could be fed into the human body through veins, arteries, or the smallest of incisions.

Click 4 Full story

Professor Katia Bertoldi and her team of researchers at Harvard University’s School of Engineering and Applied Science (SEAS) have recently developed a mathematical transformational technology that completely automates finding the best way to form a flat material into a form that can be shape shifted to perform a number of different functions.

Using this technology a designer or engineer would provide all the size and shape parameters that needs to be achieved when the object transforms from one shape into another. The program quickly finds all the possible solutions and then selects the solution that conforms to the parameters of size and shape that the researchers want as an output.

Hypothetically using this technology you could create a habitat for astronauts that folds down flat to be transported on a flight to Mars. It can also be used to create a medical device that is so small it could be fed into the human body through veins, arteries, or the smallest of incisions.

Click 4 Full story

Three Dimensional Transformers

This technology is equally successful at transforming the

outer form of a material regardless of its size.

This technology is equally successful at transforming the

outer form of a material regardless of its size.

Recent Material Science Breakthoughs

(Published March 2018 in TechDirections Magazine)

(Published March 2018 in TechDirections Magazine)

Recent Material Science Breakthoughs

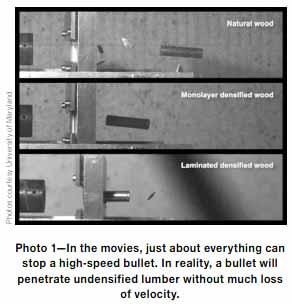

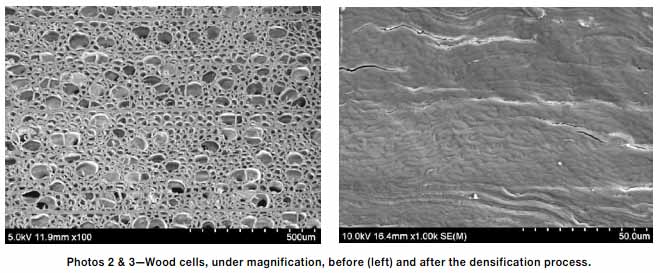

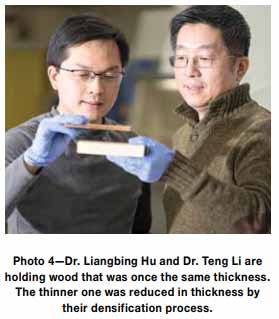

Wood that is as Tough, Hard, and Strong as Steel

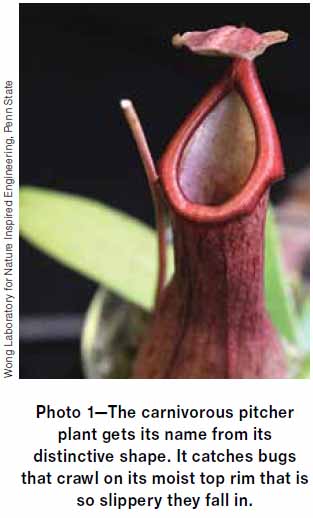

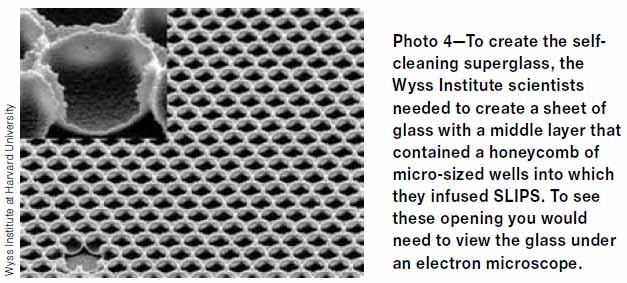

SLIPS—The Slipperiest Engineered Coating in the World

A Biologically Inspired Engineered Coating

A Biologically Inspired Engineered Coating

Biologically Inspired Engineering

At the Harvard University Wyss Institute for Biologically Inspired Engineering, scientists and engineers were able to create an ultra slippery self healing coating by duplicating the properties of the Nepenthes Pitcher plant shown in photo 1.

They named the coating that the Wyss scientists, engineers, and their students created “SLIPS” which stands for Slippery Liquid Infused Porous Surfaces. Besides being very slippery it is also transparent, self healing, durable, and basically repels everything that falls on it. See photo 2 (in column). It is much more slippery then Teflon and like Teflon it can handle very high temperatures without losing its slippery properties.

All kinds of products will soon be going on sale that are infused with SLIPS. Will you want to stick with Teflon or switch to SLIPS? You need to read the full column to fully understand this new technology?

Click 4 Full Story

At the Harvard University Wyss Institute for Biologically Inspired Engineering, scientists and engineers were able to create an ultra slippery self healing coating by duplicating the properties of the Nepenthes Pitcher plant shown in photo 1.

They named the coating that the Wyss scientists, engineers, and their students created “SLIPS” which stands for Slippery Liquid Infused Porous Surfaces. Besides being very slippery it is also transparent, self healing, durable, and basically repels everything that falls on it. See photo 2 (in column). It is much more slippery then Teflon and like Teflon it can handle very high temperatures without losing its slippery properties.

All kinds of products will soon be going on sale that are infused with SLIPS. Will you want to stick with Teflon or switch to SLIPS? You need to read the full column to fully understand this new technology?

Click 4 Full Story

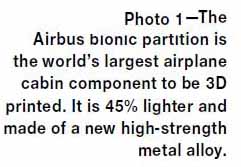

3D Printing Primed to Change the Future

A synopsis of the coverage of the topic:

For the full story click this link

Click 4 Full Story

A synopsis of the coverage of the topic:

For the full story click this link

Click 4 Full Story

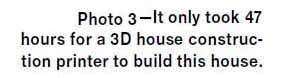

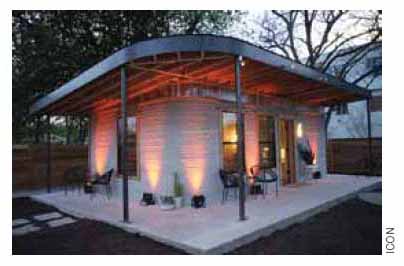

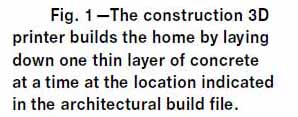

A technology that has only existed for 36 years is now changing manufacturing, construction, biotechnology, medical technology, nanotechnology, and even making it possilbe to print food from lab grown cells. It is disrupting all of the above while staying true to its simple definition of creating three dimensional objects from digital files one thin layer at a time. It went from a new way of building models and prototypes to a new way of building anything.

This metamorphous occurred when 3D printing expanded from printing plastic to printing metals,concrete, biological cells, organs, and even food. 3D printing can create parts that are lighter than but just as strong as the same part created by older methods of fabrication. See photo 1. In many technology areas 3D printing is becoming the manufacturing process. This change to additive manufacturing is accelerating in the areas of healthcare, aerospace, automotive, energy, and even consumer goods.

The images that are shown here are from the column and they show some of the objects that are being 3D printed today. As always the full column includes so much more than just the synopsis and also "Taking it a Step Further" - activities for students.

Click 4 Full Story

This metamorphous occurred when 3D printing expanded from printing plastic to printing metals,concrete, biological cells, organs, and even food. 3D printing can create parts that are lighter than but just as strong as the same part created by older methods of fabrication. See photo 1. In many technology areas 3D printing is becoming the manufacturing process. This change to additive manufacturing is accelerating in the areas of healthcare, aerospace, automotive, energy, and even consumer goods.

The images that are shown here are from the column and they show some of the objects that are being 3D printed today. As always the full column includes so much more than just the synopsis and also "Taking it a Step Further" - activities for students.

Click 4 Full Story

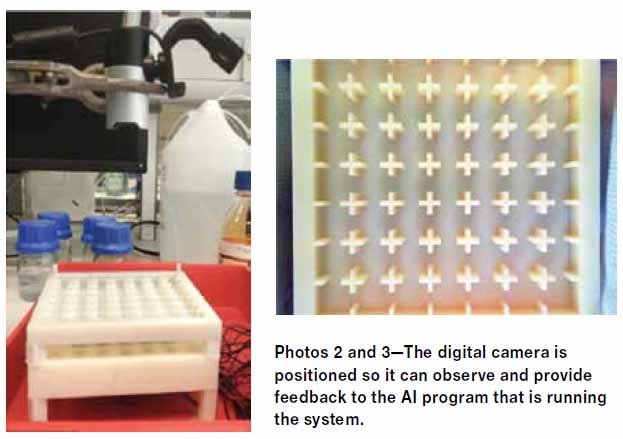

The Chemical Computer - Chemputer ™

The Chemputer ™, which I describe in this column, automatically produces complex molecules without human intervention. It is a major step toward creating a Star Trek Replicator. The TV machine could create complex solid objects, complex machines, and liquids without human intervention.

The Chemputer ™ was developed by Professor Leroy Cronin, the Regius Chair of Chemistry, at Glasgow University. BAE Systems, a British multinational aerospace company, with 85,800 employees in 40 different countries has now partnered with Glasgow University to combine the technologies of 3D printing and the Chemputer to create machines that can perform, at a slower pace, the same magic as the Star Trek Replicator. The advances in the tech originally envisioned in this BAE Systems video are now probably marked top secret.

Click 4 Full Story

The Chemputer ™ was developed by Professor Leroy Cronin, the Regius Chair of Chemistry, at Glasgow University. BAE Systems, a British multinational aerospace company, with 85,800 employees in 40 different countries has now partnered with Glasgow University to combine the technologies of 3D printing and the Chemputer to create machines that can perform, at a slower pace, the same magic as the Star Trek Replicator. The advances in the tech originally envisioned in this BAE Systems video are now probably marked top secret.

Click 4 Full Story

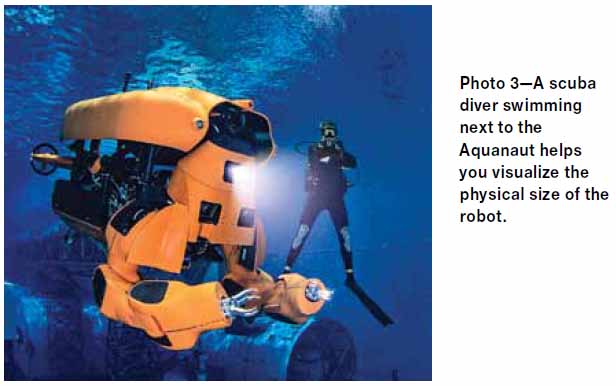

The Aquanaut Transformer

Magazine Cover Story

Magazine Cover Story

The movie Bumblebee tells the story of a transforming robot that shape shifts into a 1957 yellow Volkswagen Beetle. This Aquanaut Transformer is real and it shape shifts between a submarine and a humanoid robot. See photos 1 and 3. Its submarine shape allows it to quickly move through the water to get where it needs to be. Once there, it shape shifts into a very powerful robot capable of performing all kinds of underwater construction tasks. Its control system lets it move and work under human control for parts of its mission and under AI autonomous control for other parts of the mission. The full story is amazing.

Click for the Full Story

Click for the Full Story

Eviation is an Israeli based company with a new all electric regional airplane that can fly 621 nautical miles, at 240 knots, on a single electric charge; at the very low cost of two hundred dollars per hour of flight time. After an hour’s flight this all electric airplane, that Eviation named Alice, can recharge its lithium ion battery back to full capacity in a half hour.

Photo 1 shows Alice at this year’s Paris Air Show and its shape is as radically different from conventional airplanes as the power source that drives its engines. A careful look at photo 1 shows that two of its electric engines are located at the back of its wings and its third engine is mounted at the end of the fuselage. The full story includes how it is powered, what its artificial intelligent pilot can handle, more photos, power system, how the engines locations change flight characteristics, and what US company just purchased a full fleet of this new airplane and what routes it will soon fly.

Why is this all electric airplane such a critical achievement?

The carbon in the exhaust from a gas turbine jet engine combines with the oxygen in our atmosphere to form the global warming gas carbon dioxide. This CO2 plus the other global warming gases produced by commercial air travel is responsible for anywhere from 4 to 9 percent of the global warming that is directly caused by our industrial society.

Photo 1 shows Alice at this year’s Paris Air Show and its shape is as radically different from conventional airplanes as the power source that drives its engines. A careful look at photo 1 shows that two of its electric engines are located at the back of its wings and its third engine is mounted at the end of the fuselage. The full story includes how it is powered, what its artificial intelligent pilot can handle, more photos, power system, how the engines locations change flight characteristics, and what US company just purchased a full fleet of this new airplane and what routes it will soon fly.

Why is this all electric airplane such a critical achievement?

The carbon in the exhaust from a gas turbine jet engine combines with the oxygen in our atmosphere to form the global warming gas carbon dioxide. This CO2 plus the other global warming gases produced by commercial air travel is responsible for anywhere from 4 to 9 percent of the global warming that is directly caused by our industrial society.

Alice the All Electric Commercial Airplane

Wood - as strong as a titanium alloy

In a lab at the University of Maryland, material science and engineering professors and their students have developed a new densification process that makes common wood as strong as steel.

The basic information you need to know about wood to understand their densification process is:

1. Wood, like all plants, has hard cell walls that nature has learned how to build by combining hemicellulose and cellulose fiber.

2. Wood has a third chemical ingredient called lignin, in and between these hard walled cells.

3. Lignin acts as a natural glue and also gives the wood its ability to resist compression.

4. It is the combination of these three ingredients that gives wood its structure, hardness, and has made wood the perfect building material for thousands of years.

This column describes the densification process and where you can expect to find densified wood products in the near future.

Click 4 Full Story

In a lab at the University of Maryland, material science and engineering professors and their students have developed a new densification process that makes common wood as strong as steel.

The basic information you need to know about wood to understand their densification process is:

1. Wood, like all plants, has hard cell walls that nature has learned how to build by combining hemicellulose and cellulose fiber.

2. Wood has a third chemical ingredient called lignin, in and between these hard walled cells.

3. Lignin acts as a natural glue and also gives the wood its ability to resist compression.

4. It is the combination of these three ingredients that gives wood its structure, hardness, and has made wood the perfect building material for thousands of years.

This column describes the densification process and where you can expect to find densified wood products in the near future.

Click 4 Full Story

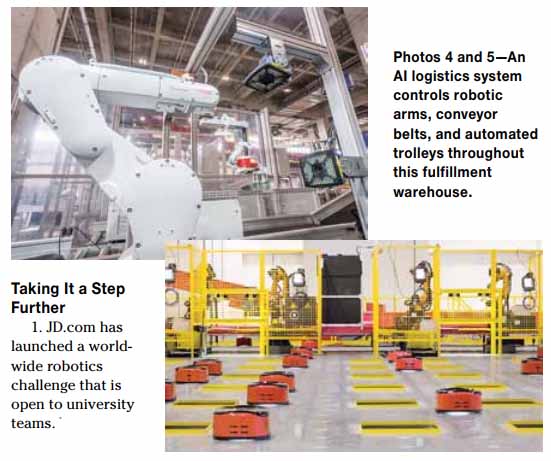

JD.com’s Totally Automated Warehouse in Shanghai

Worker Robots = 1000

Working People = 4

These Robots do the Jobs of 180 People

Working People = 4

These Robots do the Jobs of 180 People

Is your career choice or current career going to be eliminated soon by automation and/or the artificial intelligence (AI) revolution? I raise this question not to scare you but to warn you that your career choice should include insight into how your selection will be affected by smart computer algorithms or artificial intelligent robotic systems in the foreseeable future.

We are still a long way from the type of “almost human” robots often depicted in science fiction movies. However, the loss of jobs to robots that still look like machines is picking up speed. The 1,000 robots in this JD.com automated warehouse in Shanghai, China, (Photo 1) are AI-controlled to pick, package, and then ship thousands of orders each day.

The robots are now doing the jobs that would normally be done by 180 workers. JD.com is a Chinese company that most of us in the U.S. have never heard of. They are the largest retail company in China and have over 300 million customers. They use automation

wherever possible to deliver products within 48 hours from the

time they were ordered. To accomplish this task they are now even using drones to get the products to their final destination.

This column fully describes what the robots do and it includes a full video tour of the facility. JD.com has just initiated a worldwide Tech Challenge that is similar in design to the Elon Musk's Hyperloop challenge. Links to the challenge are provided in the column.

Click 4 Full story

We are still a long way from the type of “almost human” robots often depicted in science fiction movies. However, the loss of jobs to robots that still look like machines is picking up speed. The 1,000 robots in this JD.com automated warehouse in Shanghai, China, (Photo 1) are AI-controlled to pick, package, and then ship thousands of orders each day.

The robots are now doing the jobs that would normally be done by 180 workers. JD.com is a Chinese company that most of us in the U.S. have never heard of. They are the largest retail company in China and have over 300 million customers. They use automation

wherever possible to deliver products within 48 hours from the

time they were ordered. To accomplish this task they are now even using drones to get the products to their final destination.

This column fully describes what the robots do and it includes a full video tour of the facility. JD.com has just initiated a worldwide Tech Challenge that is similar in design to the Elon Musk's Hyperloop challenge. Links to the challenge are provided in the column.

Click 4 Full story

. JD.com has launched a worldwide robotics challenge that is open to university teams.

The link to the challenge is just a click away

The link to the challenge is just a click away

Beta Titanium-3 gold

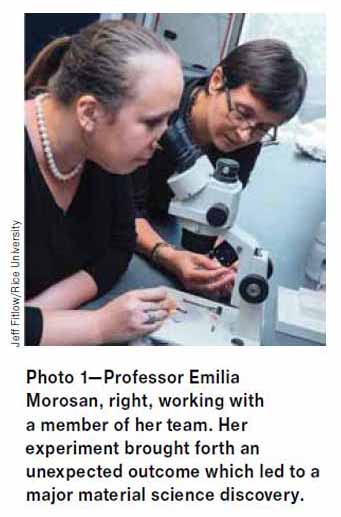

A new alloy breakthrough has Gold increasing the hardness of titanium rather than titanium increasing the hardness of gold. Dr. Morosan and her team at Rice University created it.

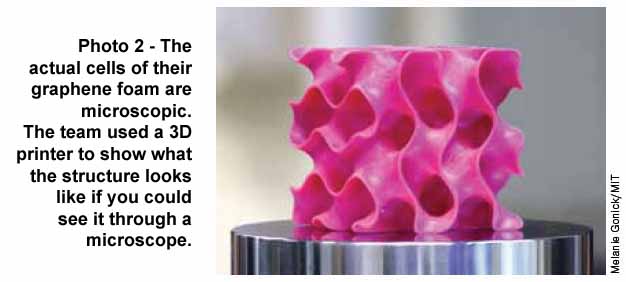

Foam Graphene

Researchers at MIT, using a similar approach, created Foam Graphene which is 10 times stronger and10 times lighter than steel. How these researchers did their magic and the possible future uses of what they created is fascinating. Click the "MIT News" image to watch a YouTube Video on foam graphene.

Breakthrough Results

These research breakthroughs have sparked a race to find new materials by doing what the researchers at Rice and MIT did to alter certain conditions during the fabrication process. Simple processing steps were changed which had a magical effect on their raw ingredients.

Click 4 Full story

A new alloy breakthrough has Gold increasing the hardness of titanium rather than titanium increasing the hardness of gold. Dr. Morosan and her team at Rice University created it.

Foam Graphene

Researchers at MIT, using a similar approach, created Foam Graphene which is 10 times stronger and10 times lighter than steel. How these researchers did their magic and the possible future uses of what they created is fascinating. Click the "MIT News" image to watch a YouTube Video on foam graphene.

Breakthrough Results

These research breakthroughs have sparked a race to find new materials by doing what the researchers at Rice and MIT did to alter certain conditions during the fabrication process. Simple processing steps were changed which had a magical effect on their raw ingredients.

Click 4 Full story

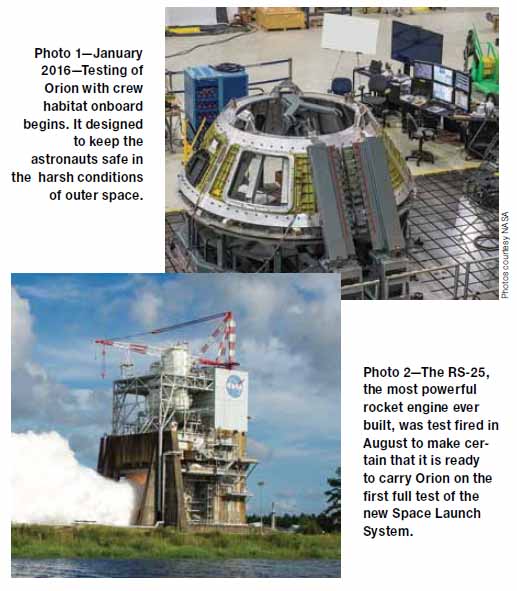

Destination Mars

The “World’s first crew to Mars is likely in middle school right now.”

The “World’s first crew to Mars is likely in middle school right now.”

Krista Alestock sent me a press release describing a Lockheed Martin contest that many teachers will want to enter. This contest has large cash prizes.

The Lockheed Martin Generation Beyond STEM Initiative, described in her press release, includes a challenge to create a very short video of a student designed “habitation module for the first crew to Mars".

Lockheed Martin is the company that is building the Orion spacecraft that will eventually land astronauts on Mars. This column provides links to the contest and also describes the hardware and how soon NASA robots and astronauts will finally start to venture beyond the moon.

This is a fascinating story and a contest that teachers will want to know about. Please forward to all teachers you feel will be interested in this subject.

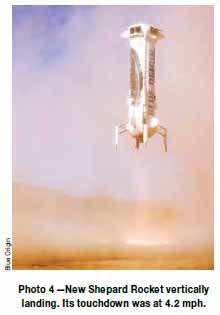

Flying into Outer Space on Reusable Rockets May/June 2016

For space flight to become as common place as air travel, rocket ships need to become as reusable as airplanes. SpaceX and Blue Origin are now in a space race that is similar to the 1960’s US versus USSR (Russia) race to the moon. Both SpaceX and Blue Origin are developing reusable rockets that can use their engines to perform a controlled descent to a vertical landing at the same location that they originally blasted off into space.

The Founders of these companies have the same goal which is to develop a rocket system that is as reliable and reusabile as an airplane. Billionaire Elon Musk is the founder of Tesla Motors and SpaceX and billionaire Jeff Bezos is the founder of Amazon.com and Blue Origin.

The Founders of these companies have the same goal which is to develop a rocket system that is as reliable and reusabile as an airplane. Billionaire Elon Musk is the founder of Tesla Motors and SpaceX and billionaire Jeff Bezos is the founder of Amazon.com and Blue Origin.

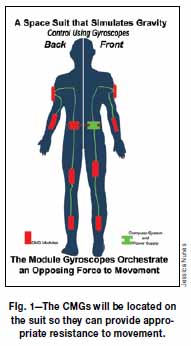

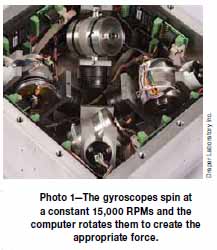

NASA’s Innovative Advances Concept Program funded research to develop a spacesuit that could deliver some form of gravity directly to the person wearing it. The idea is if you can’t bring gravity to the spaceship, perhaps you can bring the allusion of gravity to the astronaut. Sounds impossible, but collaborative efforts by engineers and technologists at Draper Laboratory Inc., MIT, and the David Clark Company have actually developed a spacesuit system that can provide an astronaut’s muscles and bones a simulated gravity.

A Space Suit

That Simulates Gravity

That Simulates Gravity

A Space Suit That Simulates Gravity

By Alan J. Pierce EdD

Yesterday’s Science Fiction—Today’s Medical Breakthrough

The movie prop that was attached to Luke Skywalker’s body, after his arm was cut off by Darth Vader in the Star Wars movie The Empire Strikes Back, was pure fiction when that movie was released back in 1980. What was once bioengineering fiction is today’s medical breakthrough.

The DEKA Luke Arm (Photo 1) is FDA (U.S. Food and Drug Administration) approved. What makes this prosthetic so amazing is that its physical movements are controlled by its wearer’s mind, just like in the movie.

The DEKA Luke Arm (Photo 1) is FDA (U.S. Food and Drug Administration) approved. What makes this prosthetic so amazing is that its physical movements are controlled by its wearer’s mind, just like in the movie.

Once a Prop From Star Wars is Now

FDA Approved

FDA Approved

Reproduced with the permission of DEKA

Research & Development Corp.

Research & Development Corp.

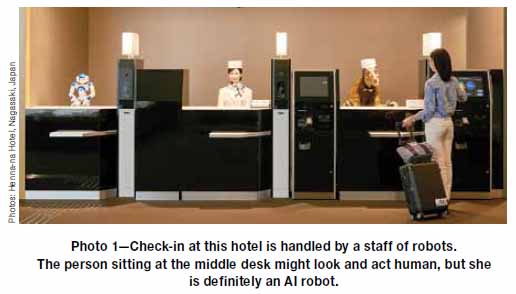

At the Henn-na Hotel, if you want to be checked in by a robot you go to line 1, by an almost human you go to line 2, or by an alligator you go to line 3. (See Photo 1.) This is the only hotel in the world fully staffed by robots and it is letting guests get a real peek at what an almost-human-intelligence robotic world might look like some day.

This hotel is located just outside the Huis Ten Bosch Amusement Park in Nagasaki, Japan. All the robotic systems of the hotel were created in Japan by the University of Tokyo, Institute of Industrial Science, and the Kajima Corporation.

A Hotel Staffed by Robots

A Hotel Staffed by Robots

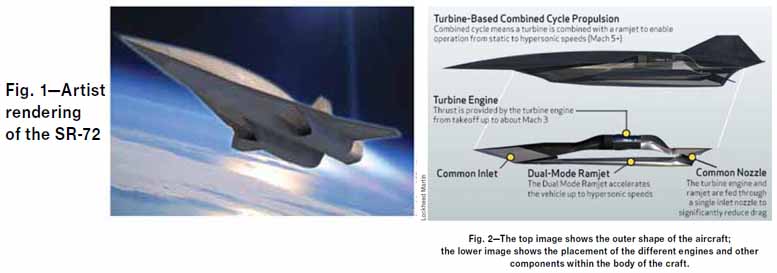

Aviation Goes Hypersonic

Fly from New York City to London England in under an hour.

(4,562 Miles Per Hour)

The speed of sound is called Mach 1 and equals 761.2 miles per hour. The fastest plane ever flown so far is the Lockheed Martin SR-71 Blackbird spy plane. It flew at Mach 3.5. The “Son of Blackbird is now under construction and it will fly at hypersonic speeds of Mach 6. This plane will have the same turbo-jet engine that powered the SR-7 and a ramjet engine to push propulsion up to Mach 6.

At Mach 6 the SR-72 will cover one mile of ground per second of flight time. This is an amazing story of the future of flight and the full story is just one click away.

Fly from New York City to London England in under an hour.

(4,562 Miles Per Hour)

The speed of sound is called Mach 1 and equals 761.2 miles per hour. The fastest plane ever flown so far is the Lockheed Martin SR-71 Blackbird spy plane. It flew at Mach 3.5. The “Son of Blackbird is now under construction and it will fly at hypersonic speeds of Mach 6. This plane will have the same turbo-jet engine that powered the SR-7 and a ramjet engine to push propulsion up to Mach 6.

At Mach 6 the SR-72 will cover one mile of ground per second of flight time. This is an amazing story of the future of flight and the full story is just one click away.

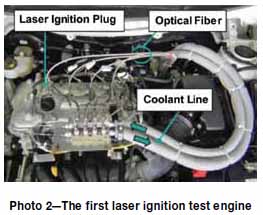

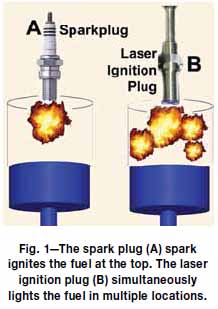

The Laser Automobile Ignition System

If we were to compare an automobile to a living organism, we might consider its spark plugs the source of energy that causes the heart of the engine to beat. The exploding air-gasoline mixture in the cylinders, which drives the car, can be compared to the pumping heart muscle that provides the energy needed for movement. Just as exercise can strengthen the heart of a living organism, a laser ignition plug that can simultaneously ignite the air-gas mixture in multiple locations would greatly improve the efficiency of the engine.

Takunori Taira and his associates at Japan’s National Institute of Natural Sciences, working with Toyota Motors, Nippon Sokem Inc., and the Denso Corporation, have successfully built a fully functional laser ignition system. Their laser ignition plug is shown in Photo 1 and the test engine that they built is shown in Photo 2. They demonstrated the world’s first gasoline engine micro laser ignition car in 2013.

Takunori Taira and his associates at Japan’s National Institute of Natural Sciences, working with Toyota Motors, Nippon Sokem Inc., and the Denso Corporation, have successfully built a fully functional laser ignition system. Their laser ignition plug is shown in Photo 1 and the test engine that they built is shown in Photo 2. They demonstrated the world’s first gasoline engine micro laser ignition car in 2013.

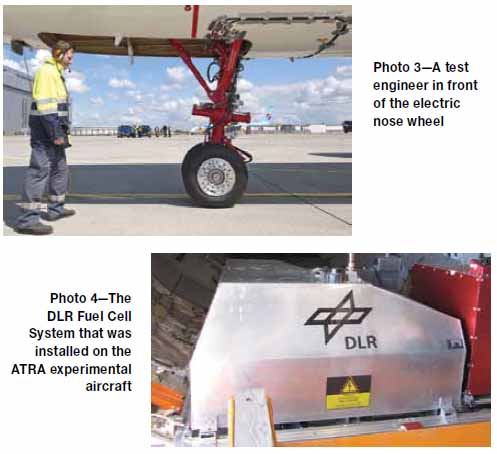

The Hybrid Commercial Jet Plane

Hybrid cars are now very common. The question becomes how soon will hybrid technology be adopted for commercial airplanes? Engineers have already proven that the same benefits of hybrid car technology can be transformed so they can save fuel and maintenece costs on commercial airplanes. Before this technology can be fully adopted and find its way into the planes at your local airport they need to be fully tested.

The A320 ATRA (Advanced Technology

Research Aircraft), a DLR research

airplane (See Photo 1) is now performing the test. The goal is to prove it is safe, efficient, and

cost effective. If testing pans out and

broad adoption takes place, eventually

all new commercial jet planes could be categorized as hybrid vehicles. The full story is fascinating.

The A320 ATRA (Advanced Technology

Research Aircraft), a DLR research

airplane (See Photo 1) is now performing the test. The goal is to prove it is safe, efficient, and

cost effective. If testing pans out and

broad adoption takes place, eventually

all new commercial jet planes could be categorized as hybrid vehicles. The full story is fascinating.

Sky-High Elevators Without Cables

Modern elevators are pulled up and lowered down by very strong cables. To design and build a mile high building you need to eliminate the current cable system because cables that long are to0 heavy.

ThyssenKrupp engineers decided to get rid of the cable that lifts and lowers an elevator in its shaft. To accomplish this task they adapted the magnetic levitation system that they had designed to levitate their Transrapid high speed Maglev monorail trains. They repurposed this maglev system so it could work in an elevator shaft. For the complete story click the link below.

ThyssenKrupp engineers decided to get rid of the cable that lifts and lowers an elevator in its shaft. To accomplish this task they adapted the magnetic levitation system that they had designed to levitate their Transrapid high speed Maglev monorail trains. They repurposed this maglev system so it could work in an elevator shaft. For the complete story click the link below.

The New Tappan Zee Bridge

This new Tappan Zee Bridge is just beginning to rise from the water of the Hudson River. This column describes the engineering and construction technologies being used to build this new bridge. These bridges will withstand the forces of nature that are now slowly ripping apart the 60 year old Tappan Zee bridge that it will soon replace.

To build a structurally sound bridge, this time, engineers needed to reach the bedrock which is 300 feet below the water and covered by hundreds of feet of silt. The new twin Bridges will have a dampening system that will allow them to withstand the motion of an earthquake if, perhaps when, the Ramapo seismic zone decides to give them a major shake. The full story is fascinating.

To build a structurally sound bridge, this time, engineers needed to reach the bedrock which is 300 feet below the water and covered by hundreds of feet of silt. The new twin Bridges will have a dampening system that will allow them to withstand the motion of an earthquake if, perhaps when, the Ramapo seismic zone decides to give them a major shake. The full story is fascinating.

The New Tappan Zee Bridge

Click the "Select a Link" Below to Explore

our coverage of our tecnological world.

our coverage of our tecnological world.

A Copyright © on the date of publication exists for all articles and other material posted on this website. With proper citation you are welcome to use all the materials in your classroom.

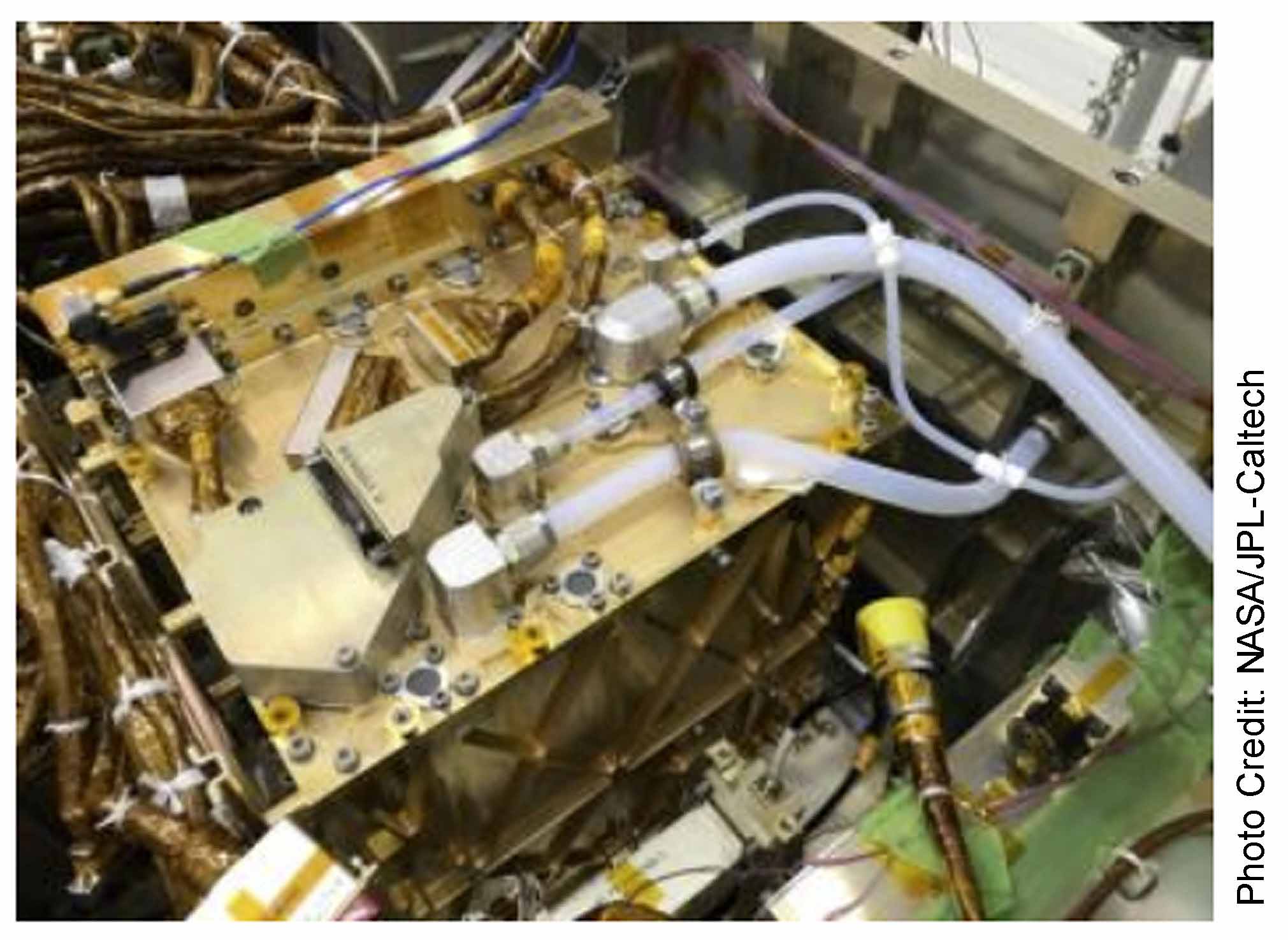

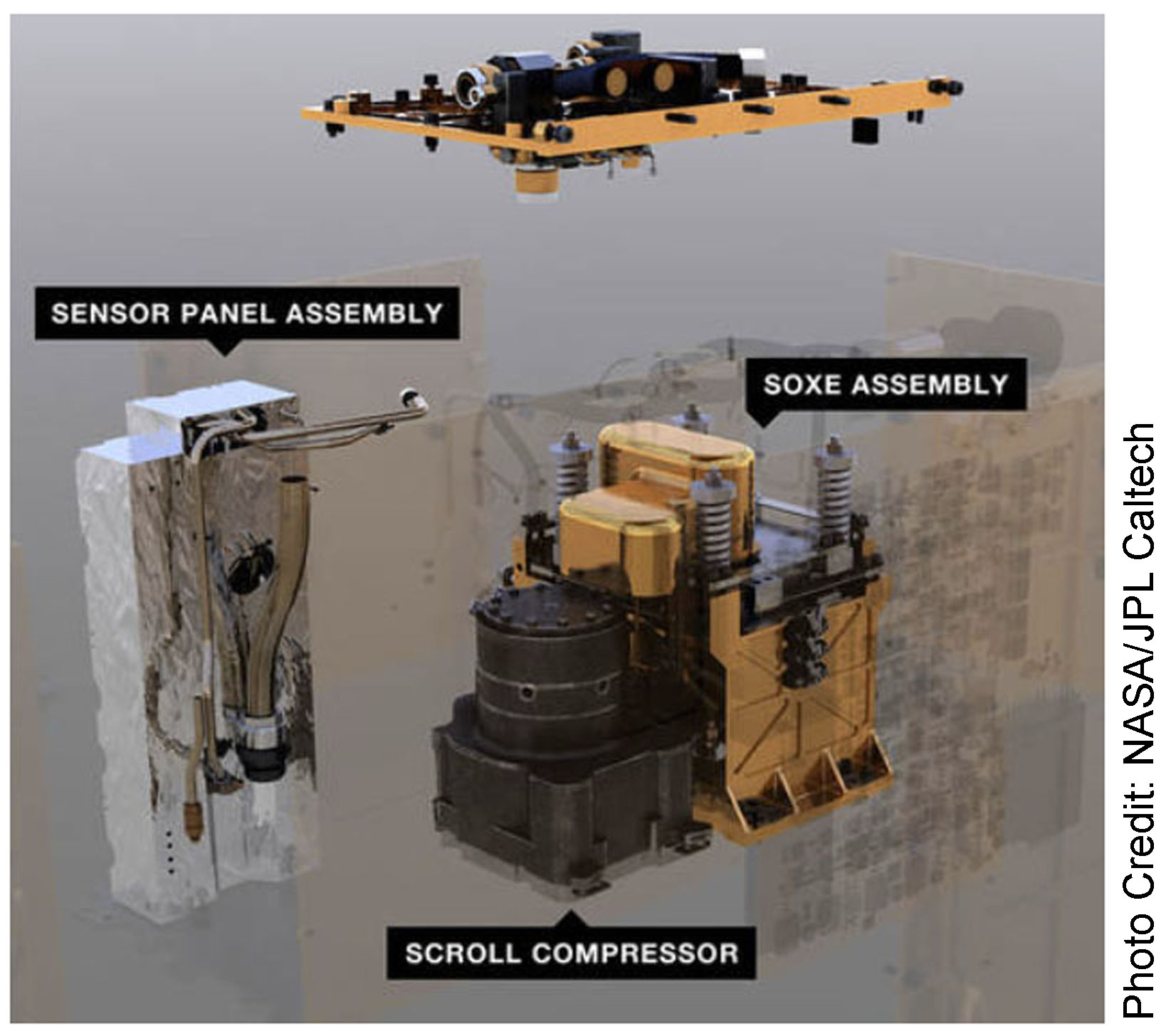

Creating Oxygen and Rocket Fuel on Mars

May/June 2021

We need oxygen to breathe and for people to live on Mars they will need oxygen for respiration. They will also need oxygen to fuel their rockets or astronauts will never be able to return to earth. To blast off the red planet, a rocket would need an enormous quantity of rocket fuel (15,000 lbs) and even a greater quantity of oxygen (55,000 lbs). The goal is to eventually be able to manufacture both oxygen and rocket fuel, in the needed quantities, using Martian indigenous materials. The process to create oxygen has now been tested on Mars and the technology to create rocket fuel is now being developed on earth. Full story explains the processes.

Click 4 the Full Story Printable PDF

May/June 2021

We need oxygen to breathe and for people to live on Mars they will need oxygen for respiration. They will also need oxygen to fuel their rockets or astronauts will never be able to return to earth. To blast off the red planet, a rocket would need an enormous quantity of rocket fuel (15,000 lbs) and even a greater quantity of oxygen (55,000 lbs). The goal is to eventually be able to manufacture both oxygen and rocket fuel, in the needed quantities, using Martian indigenous materials. The process to create oxygen has now been tested on Mars and the technology to create rocket fuel is now being developed on earth. Full story explains the processes.

Click 4 the Full Story Printable PDF

Just Scroll Down

For More Engineering Technology Breakthroughs

For More Engineering Technology Breakthroughs

Providing Resources on New & Emerging Tech for Technology Literacy

Alan J. Pierce EdD

pierceaj@techtoday.us

pierceaj@techtoday.us